Khetha: Imikhiqizo ye-gearbox eyi-Dual-clutch imanzi i-dual-clutch gearbox, igobolondo elisekelayo liqukethe igobolondo le-clutch kanye ne-gearbox, amagobolondo amabili akhiqizwa indlela yokuphonsa umfutho ophezulu, ekuthuthukisweni komkhiqizo kanye nokukhiqizwa kuhlangabezane nenqubo yokuthuthukisa ikhwalithi enzima. , isilinganiso esiphelele esiphelele esingenalutho cishe ngo-60% 95% ekupheleni kokunyukela kumazinga angu-2020, Lesi sihloko sifinyeza izixazululo zezinkinga zekhwalithi ezijwayelekile.

I-Wet dual-clutch transmission, esebenzisa isethi yegiya le-cascade emisha, isistimu ye-electro-mechanical shift drive kanye ne-electro-hydraulic clutch actuator entsha. Igobolondo elingenalutho lenziwe nge-high pressure casting aluminium alloy, enezici zesisindo sokukhanya namandla aphezulu. Kukhona iphampu ye-hydraulic, uketshezi olugcobayo, ipayipi lokupholisa kanye nesistimu yokupholisa yangaphandle ku-gearbox, okubeka phambili izidingo eziphakeme ekusebenzeni okuphelele kokusebenza nokusebenza kokuvala kwegobolondo. Leli phepha lichaza ukuthi zingaxazululwa kanjani izinkinga zekhwalithi ezifana nokuguqulwa kwamagobolondo, imbobo yokuncipha komoya kanye nezinga lokuphasa elivuzayo elithinta kakhulu izinga lokuphasa.

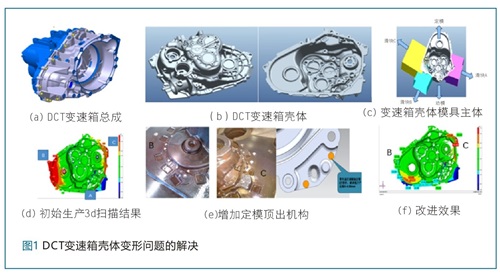

1,Isixazululo senkinga ye-deformation

Umfanekiso 1 (a) ngezansi,U-gearbox wakhiwe nge-high-pressure cast cast aluminium alloy gearbox housing kanye ne-clutch housing. Izinto ezisetshenziswayo yi-ADC12, futhi ugqinsi lwalo oluyisisekelo lungaba ngu-3.5mm. Igobolondo le-gearbox liboniswa kuMfanekiso 1 (b). Usayizi oyisisekelo ngu-485mm (ubude) × 370mm (ububanzi) × 212mm (ubude), ivolumu ingu-2481.5mm3, indawo ehlongozwayo ingu-134903mm2, kanti isisindo senetha singaba ngu-6.7kg. Kuyingxenye yembobo ejulile enezindonga ezincane. Uma kucatshangelwa ubuchwepheshe bokukhiqiza nokucubungula isikhunta, ukwethembeka kokubunjwa komkhiqizo kanye nenqubo yokukhiqiza, isikhunta sihlelwa njengoba kukhonjisiwe kuMfanekiso 1 (c), owakhiwe ngamaqembu amathathu ezilayidi, isikhunta esinyakazayo (ngasohlangothini lwangaphandle). i-cavity) kanye nesikhunta esinqunyiwe (esiqondisweni se-cavity yangaphakathi), futhi izinga lokunciphisa okushisayo lokuphonsa lenzelwe ukuba libe ngu-1.0055%.

Eqinisweni, ngesikhathi sokuhlolwa kokuqala kokukhishwa kwefa, kwatholakala ukuthi usayizi wendawo yomkhiqizo okhiqizwa i-die casting wawuhluke kakhulu ezidingweni zokuklama (ezinye izikhundla zazingaphezu kuka-30% isaphulelo), kodwa usayizi wesikhunta wawufanelekile futhi izinga lokuncipha uma liqhathaniswa nosayizi wangempela nalo lalihambisana nomthetho wokuncipha. Ukuze kutholwe imbangela yenkinga, ukuskena kwe-3D kwegobolondo elibonakalayo kanye ne-3D yethiyori kwasetshenziswa ukuze kuqhathaniswe nokuhlaziya, njengoba kukhonjisiwe kuMfanekiso 1 (d). Kwatholakala ukuthi indawo yokuma eyisisekelo yento engenalutho ikhubazekile, futhi inani lokuguqulwa lalingu-2.39mm endaweni B kanye no-0.74mm endaweni C. Ngoba umkhiqizo usekelwe endaweni eyi-convex ye-A, B, C engenalutho elandelayo. icubungula ibhentshimakhi yokuma kanye nebhentshimakhi yokulinganisa, lokhu kuguqulwa kuholela esilinganisweni, okunye ukuqagela kosayizi ku-A, B, C njengesisekelo sendiza, indawo yembobo ayisebenzi.

Ukuhlaziywa kwezimbangela zale nkinga:

①Isimiso somklamo we-high pressure casting die ngomunye wemikhiqizo ngemva kokudilizwa, ukunikeza isimo somkhiqizo kumodeli eguqukayo, edinga umphumela kumodeli eguquguqukayo yamandla ephakeji mkhulu kunamandla asebenza kusikhwama sesikhunta esigxilile, ngenxa imikhiqizo ekhethekile yomgodi ojulile ngasikhathi sinye, umgodi ojulile ngaphakathi kwama-cores esikhunjeni esingaguquki nangaphandle kwakhiwe indawo engaphezulu kwemikhiqizo yesikhunta enyakazayo ukunquma isiqondiso sokuhlukaniswa kwesikhunta lapho kuzohlupheka nakanjani ukudonsa;

②Kunamaslayida ohlangothini lwesobunxele, oluphansi nolwesokudla lwesikhunta, adlala indima eyisizayo ekubambeni ngaphambi kokudilizwa. Amandla amancane okusekela angaphezulu kuka-B, futhi ukuthambekela okuphelele kuwukugoqa emgodini ngesikhathi sokuncipha kokushisa. Izizathu ezimbili ezingenhla eziyinhloko ziholela ekuguquguqukeni okukhulu kakhulu ku-B, kulandele u-C.

Uhlelo lokuthuthukisa lokuxazulula le nkinga ukwengeza indlela yokukhipha ukufa okugxilile Umfanekiso 1 (e) endaweni engaguquki yokufa. Ku-B kukhuphuke i-plunger yokubumba eyi-6, yengeza i-plunger yesikhunta egxilile ku-C, iphinikhodi engaguquki iwukuthembela ekusetheni kabusha, lapho indiza yokumisa isikhunta isetha i-reset lever icindezela ibe isikhunta, isikhunta esizenzakalelayo sokufa siyanyamalala, ingemuva of the spring plate bese ucindezela isiqongo esiphezulu, thatha isinyathelo ukukhuthaza imikhiqizo iphuma isikhunta fixed, ukuze uqaphele offset demoulding deformation.

Ngemuva kokuguqulwa kwesikhunta, i-deformation deformation incishiswa ngempumelelo. Njengoba kuboniswe ku-FIG.1 (f), ukuguqulwa ku-B no-C kulawulwa ngempumelelo. Iphuzu B lingu-+0.22mm kanye nephoyinti C lingu-+0.12, elihlangabezana nemfuneko yekhonta engenalutho engu-0.7mm futhi kuzuzwe ukukhiqizwa ngobuningi.

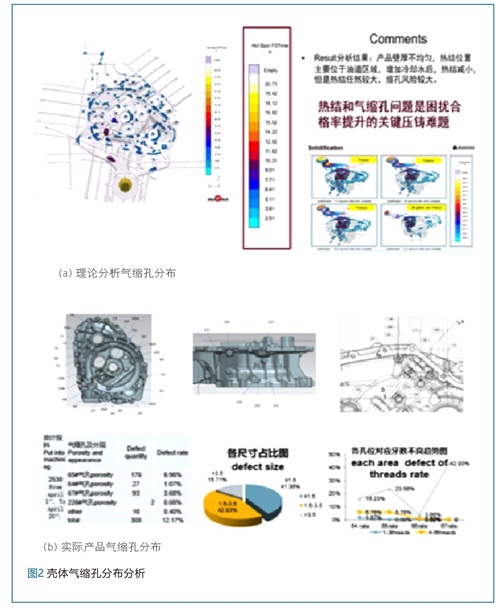

2, Isixazululo sembobo yokuncipha kwegobolondo nokuvuza

Njengoba kwaziwa yibo bonke, ukukhishwa kwengcindezi ephezulu kuyindlela yokwenza lapho insimbi ewuketshezi igcwaliswa khona ngokushesha emgodini wesikhunta sensimbi ngokusebenzisa ingcindezi ethile futhi iqina ngokushesha ngaphansi kwengcindezi yokuthola ukukhishwa. Kodwa-ke, kuncike ezicini zokuklanywa komkhiqizo kanye nenqubo yokukhipha ukufa, kusenezindawo ezithile zamalunga ashisayo noma izimbobo eziyingozi kakhulu zokuncipha komoya emkhiqizweni, okubangelwa:

(1) Ukukhipha ingcindezi kusebenzisa ingcindezi ephezulu ukuze ucindezele insimbi ewuketshezi endaweni yokubumba ngesivinini esikhulu. Igesi elisegunjini lokucindezela noma isikhunta asikwazi ukukhishwa ngokuphelele. Lawa magesi ahilelekile ensimbi ewuketshezi futhi ekugcineni akhona ekubunjweni ngendlela yama-pores.

(2) Ukuncibilika kwegesi ku-aluminium ewuketshezi nengxube ye-aluminium eqinile kuhlukile. Enqubweni yokuqinisa, igesi iyancipha ngokungenakugwenywa.

(3) Insimbi ewuketshezi iqina ngokushesha emgodini, futhi esimweni lapho kungabikho ukuphakelwa okuphumelelayo, ezinye izingxenye zokuphonsa zizokhiqiza umgodi wokushwabana noma ukushwabana kwe-porosity.

Thatha imikhiqizo ye-DPT engene ngokulandelana kwesampula yamathuluzi kanye nesiteji sokukhiqiza inqwaba njengesibonelo (bona Umfanekiso 2) : Izinga lokukhubazeka lembobo yokuqala yokuncipha komoya yomkhiqizo libaliwe, futhi eliphakeme kakhulu lalingu-12.17%, phakathi kwalo umoya. Imbobo yokuncipha enkulu kuno-3.5mm ibalwe ku-15.71% wesamba sokukhubazeka, kanti imbobo yokuncipha komoya phakathi kuka-1.5-3.5mm ibalwa ku-42.93%. Lezi zimbobo zokuncipha komoya bezigxilwe kakhulu kwezinye izimbobo ezinentambo nasezindaweni zokuvala. Lezi zinkinga zizothinta amandla okuxhumeka kwe-bolt, ukuqina kwendawo kanye nezinye izidingo zokusebenza ze-scrap.

Ukuxazulula lezi zinkinga, izindlela eziyinhloko zimi kanje:

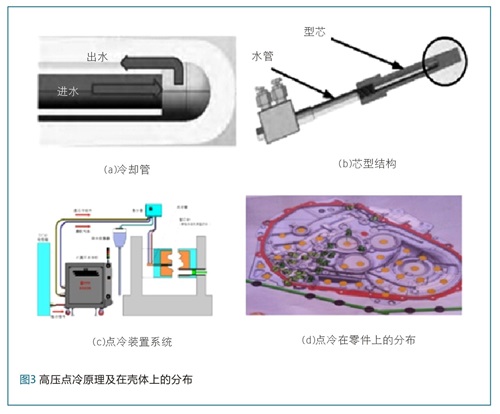

2.1UHLELO LOKUPHOLISA INDAWO

Ifanele izingxenye zesikhala esisodwa esijulile kanye nezingxenye eziyinhloko. Ingxenye eyakha yalezi zakhiwo inezimbotshana ezimbalwa ezijulile kuphela noma ingxenye ejulile yomgodi wokudonsa umnyombo, njll., futhi isikhunta esincane esongwe inani elikhulu le-aluminium ewuketshezi, okulula ukubangela ukushisa kwesikhunta, okubangela ukunamathela. uhlobo lwesikhunta, ukuqhekeka okushisayo nezinye iziphambeko. Ngakho-ke, kuyadingeka ukuphoqa ukupholisa amanzi okupholisa endaweni yokudlula yesikhunta esijulile somgodi. Ingxenye engaphakathi yomgogodla enobubanzi obukhulu kuno-4mm ipholiswe ngamanzi angu-1.0-1.5mpa aphezulu, ukuze kuqinisekiswe ukuthi amanzi okupholisa ayabanda futhi ayashisa, futhi izicubu ezizungezile zomgogodla zingaqala ukuqina futhi zenze ungqimba oluminyene, ukuze kuncishiswe ukushwabana nokuthambekela kwe-porosity.

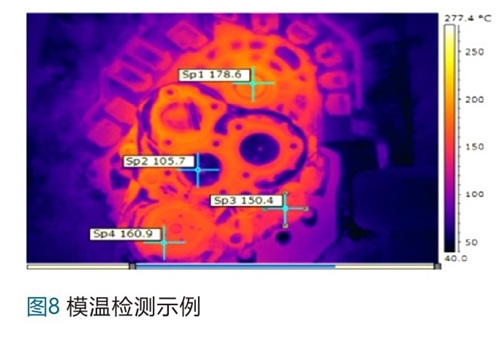

Njengoba kuboniswe kuMfanekiso 3, kuhlanganiswe nedatha yokuhlaziywa kwezibalo yokulingisa kanye nemikhiqizo yangempela, indawo yokugcina yokupholisa yathuthukiswa, futhi ukupholisa iphuzu lokucindezela okukhulu njengoba kuboniswe kuMfanekiso 3 (d) kwakubekwe esikhunjeni, esilawula ngokuphumelelayo. izinga lokushisa lomkhiqizo endaweni ehlangene eshisayo, laqaphela ukuqiniswa okulandelanayo kwemikhiqizo, lanciphisa ngokuphumelelayo ukukhiqizwa kwezimbobo zokuncipha, futhi laqinisekisa izinga elifanelekayo.

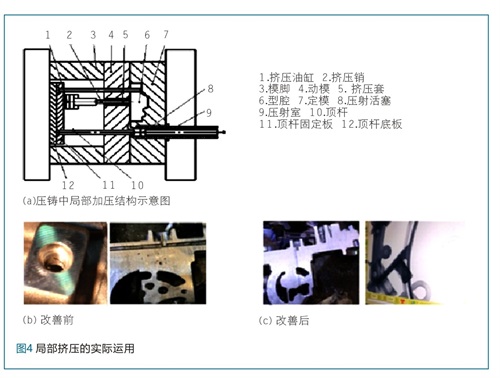

2.2I-extrusion yendawo

Uma ubukhulu bodonga bomklamo wesakhiwo somkhiqizo bungalingani noma kukhona ama-node amakhulu ashisayo kwezinye izingxenye, izimbobo zokuncipha zivame ukubonakala engxenyeni yokugcina eqinile, njengoba kuboniswe ku-FIG. 4 (C) ngezansi. Izimbobo zokuncipha kule mikhiqizo azikwazi ukuvinjelwa inqubo yokufaka ukufa kanye nokwandisa indlela yokupholisa. Ngalesi sikhathi, i-extrusion yendawo ingasetshenziswa ukuxazulula inkinga. Umdwebo wesakhiwo sokucindezela ingxenye njengoba kukhonjisiwe kumfanekiso 4 (a), okungukuthi ofakwe ngokuqondile kusilinda sesikhunta, ngemva kokugcwalisa insimbi encibilikisiwe esibunjeni futhi yaqina ngaphambili, hhayi ngokuphelele oketshezini lwensimbi olulingana nengxenye embotsheni, ekugcineni. ukuqiniswa kodonga oluwugqinsi ngokucindezela kwenduku ye-extrusion okuphoqelelwe ukuncelisa ukunciphisa noma ukuqeda amaphutha alo omgodi wokushwabana, ukuze kutholwe izinga eliphezulu lokuphonsa ukufa.

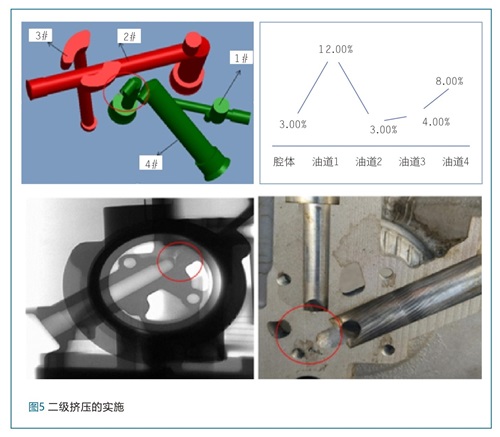

2.3I-extrusion yesibili

Isigaba sesibili se-extrusion ukusetha isilinda sokushaya kabili. I-stroke yokuqala iqeda ukubumba ingxenye yembobo yokuqala yokusakazwa, futhi lapho i-aluminium ewuketshezi ezungeze umnyombo iqiniswa kancane kancane, isenzo sesibili sokukhipha siyaqalwa, futhi umphumela ophindwe kabili wokusakazwa kwangaphambili nokukhishwa ekugcineni uyabonakala. Thatha indlu ye-gearbox njengesibonelo, izinga elifanelekile lokuhlolwa kwegesi ye-gearbox yezindlu esigabeni sokuqala sephrojekthi lingaphansi kwama-70%. Ukusatshalaliswa kwezingxenye zokuvuza ikakhulukazi ukuphambana kwephaseji kawoyela 1# kanye nephaseji kawoyela 4# (umbuthano obomvu kuMfanekiso 5) njengoba kukhonjisiwe ngezansi.

2.4UHLELO LWE-RUNNER

Isistimu yokuphonsa yesikhunta se-metal die casting iwumzila ogcwalisa umgodi wemodeli yokufa ngoketshezi lwensimbi oluncibilikisiwe ekamelweni lokunyathelisa lomshini wokukhipha ukufa ngaphansi kwesimo sokushisa okuphezulu, ukucindezela okukhulu kanye nesivinini esikhulu. Kuhlanganisa umgijimi oqondile, umgijimi ophambanayo, umgijimi wangaphakathi kanye nesistimu yokukhipha umoya ochichimayo. Baqondiswa kunqubo ye-liquid metal filling cavity, isimo sokugeleza, isivinini kanye nokucindezela kokudluliswa kwensimbi ewuketshezi, umphumela we-exhaust kanye nesikhunta se-die udlala indima ebalulekile ezicini ezifana nesimo sokulinganisa okushisayo sokulawula nokulawula, ngakho-ke. , i-gating system inqunywa ukuthi izofa ikhwalithi ye-casting surface kanye nesici esibalulekile sesimo se-microstructure yangaphakathi. Ukuklama nokuphothulwa kohlelo lokuthulula kumele kusekelwe ekuhlanganisweni kwethiyori nokwenza.

2.5Pi-rocessOukwenziwa ngcono

Inqubo ye-Die casting iyinqubo yokucubungula okushisayo ehlanganisa futhi isebenzise umshini wokuphonsa ifa, i-die casting die kanye nensimbi ewuketshezi ngokuya ngenqubo yenqubo ekhethwe ngaphambili kanye nemingcele yenqubo, futhi ithola ukukhishwa kwefa ngosizo lokushayela kwamandla. Kuthatha zonke izinhlobo zezinto ezicatshangelwayo, Njengokucindezela (okuhlanganisa amandla omjovo, ingcindezi ethile yomjovo, amandla okunweba, amandla okukhiya isikhunta), isivinini somjovo (okuhlanganisa isivinini sokubhoboza, isivinini sangaphakathi sesango, njll.), Isivinini sokugcwalisa, njll.) , amazinga okushisa ahlukahlukene (izinga lokushisa elincibilikayo lensimbi ewuketshezi, izinga lokushisa lokufa, izinga lokushisa lesikhunta, njll.), izikhathi ezihlukahlukene (isikhathi sokugcwalisa, isikhathi sokubamba ingcindezi, isikhathi sokugcina isikhunta, njll.), izakhiwo ezishisayo zesikhunta (izinga lokudlulisa ukushisa, ukushisa izinga lomthamo, izinga lokushisa, i-gradient, njll.), izakhiwo zokuphonsa kanye nezakhiwo ezishisayo zensimbi ye-liquid, njll. Lokhu kudlala indima ehamba phambili ekucindezelweni kwe-die casting, isivinini sokugcwalisa, izici zokugcwalisa kanye nezakhiwo ezishisayo zesikhunta.

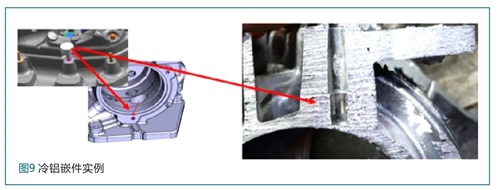

2.6Ukusetshenziswa kwezindlela ezintsha

Ukuze kuxazululwe inkinga yokuvuza kwezingxenye ezixekethile ngaphakathi kwezingxenye ezithile zegobolondo le-gearbox, isixazululo se-aluminium block ebandayo sasetshenziswa ukuphayona ngemuva kokuqinisekiswa yizinhlangothi zombili zokuhlinzeka nezidingo. Okusho ukuthi, ibhulokhi ye-aluminium ilayishwa ngaphakathi komkhiqizo ngaphambi kokugcwalisa, njengoba kuboniswe kuMfanekiso 9. Ngemva kokugcwalisa nokuqinisa, lokhu kufakwa kuhlala ngaphakathi kwengxenye yebhizinisi ukuxazulula inkinga yokuncipha kwendawo kanye ne-porosity.

Isikhathi sokuthumela: Sep-08-2022